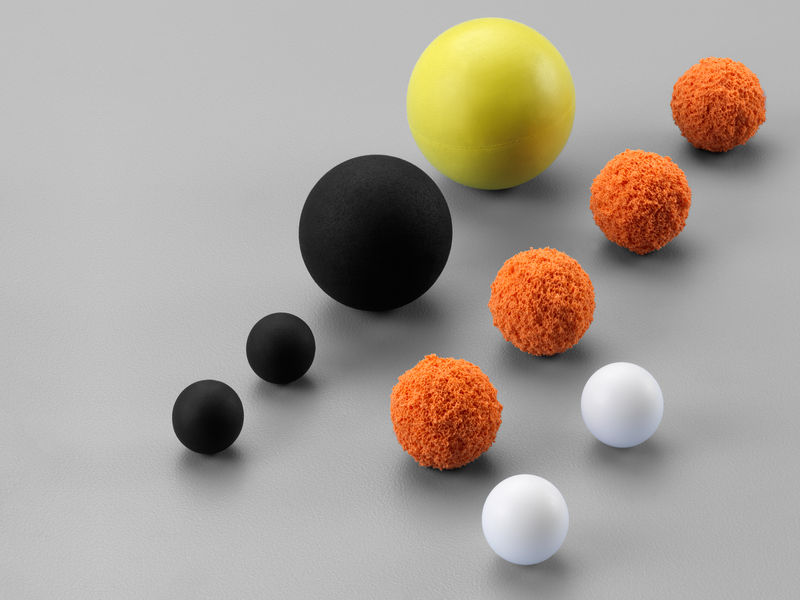

Rubber and plastic balls - Durable and versatile

Rubber and plastic balls are mainly used as seals in valves and pumps or for cleaning pipelines, heating systems and screening systems. Depending on the requirements, we use different types of rubber for our rubber balls in order to be able to offer the right material properties for every application. For this reason, our valve balls and strainer cleaning balls can be found in many areas of the chemical industry as well as in mechanical and plant engineering. Our rubber and plastic balls are characterized by their high durability and resistance.

Quickfacts Rubber and plastic balls

Application

Valve balls, sieve knocking balls, cleaning balls

Materials

NR, SBR, EPDM, CR, NBR, SI, FPM/FKM

Core materials

Hardness

Colors

Quantity

Manufacture

CM, TM, IM

Dimensions

| Application | Valve balls, sieve knocking balls, cleaning balls |

| Materials | NR, SBR, EPDM, CR, NBR, SI, FPM/FKM |

| Core materials | e.g. wood, cork, steel, cast iron, aluminum, hollow steel cores |

| Hardness | 35 ± 5 Shore A to 85 ± 5 Shore A |

| Colors | on request |

| Quantity | as of 1 |

| Manufacture | CM, TM, IM |

| Dimensions | Ø 3.2 - 300 mm (others on request) |

Request a free sample now

Further details in the catalog

Request a free sample now

Rubber valve balls

In valves, rubber balls act as a common shut-off device, preventing the unwanted backflow of gases, liquids or granular substances and dusts. The freely movable rubber ball is located in the cage of the ball valve and is lifted out of the valve seat by the inflowing medium.

In the event of backflow, the ball is pressed back into the hard valve seat by force and its own weight, thereby creating a seal. The valve seat should be adapted to the material used for the valve ball.

Another field of application is the area of float balls. Ball concepts with buoyant elastomers and core materials are used here. We have suitable elastomer and plastic materials available for the various specific operating conditions.

Screen cleaning balls made of rubber with high rebound resilience

Our rubber balls are used for cleaning industrial screening systems. The balls are added to the material to be screened and, due to their bouncing behavior, ensure permanently recurring collisions with other balls, with the material to be screened and with the screen itself. These recurring impulses keep the screen passages clear.

In order to counteract the resulting abrasion pressure and ensure the required bounce behavior, we use materials that are characterized by low abrasion and good rebound elasticity. This achieves the best possible results during the cleaning process.

Our expertise in the field of rubber screen cleaning balls enables us to produce a wide range of standard sizes as well as numerous intermediate sizes in various degrees of hardness to suit your specific sealing application.

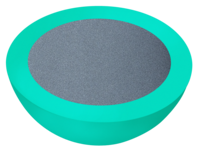

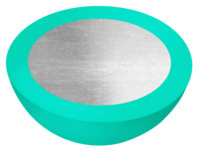

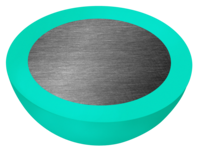

Cores

Ball with lead

Ball with cork

Ball with wood

Ball with aluminum

Ball with steel

Ball with casting

Blog

Blog

Blog

Blog

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161