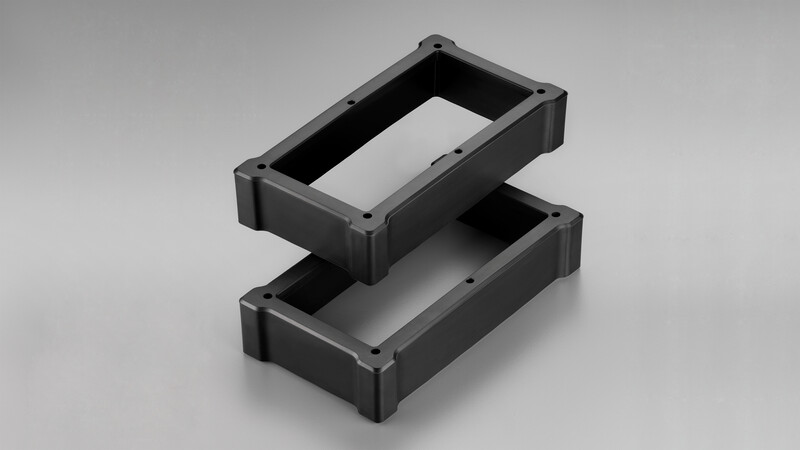

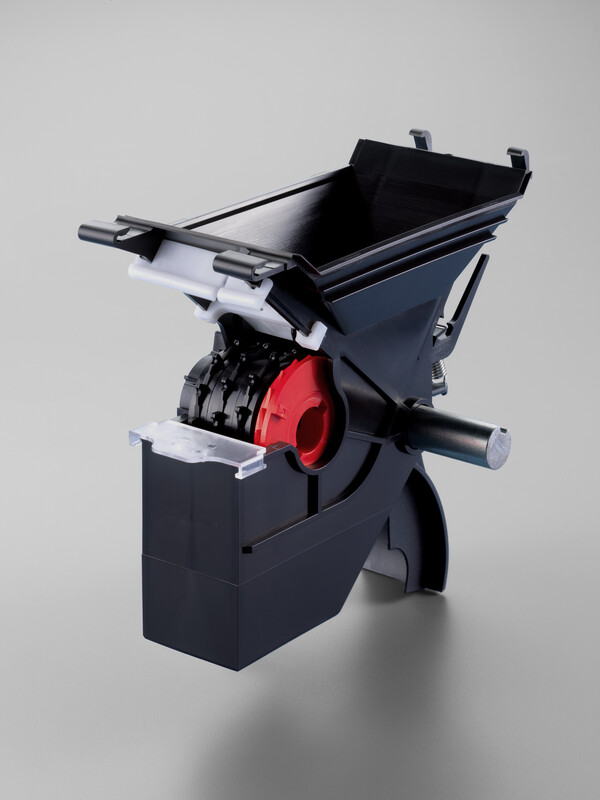

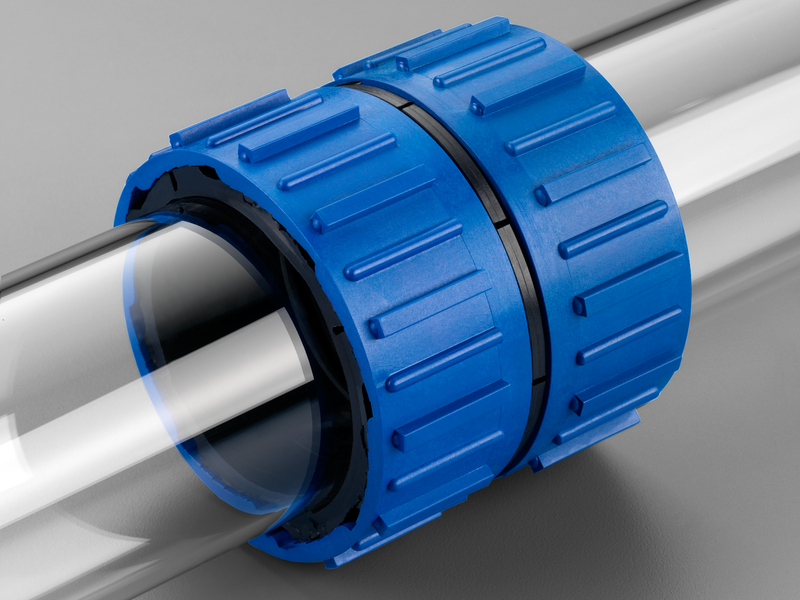

Construction elements from small series to large series

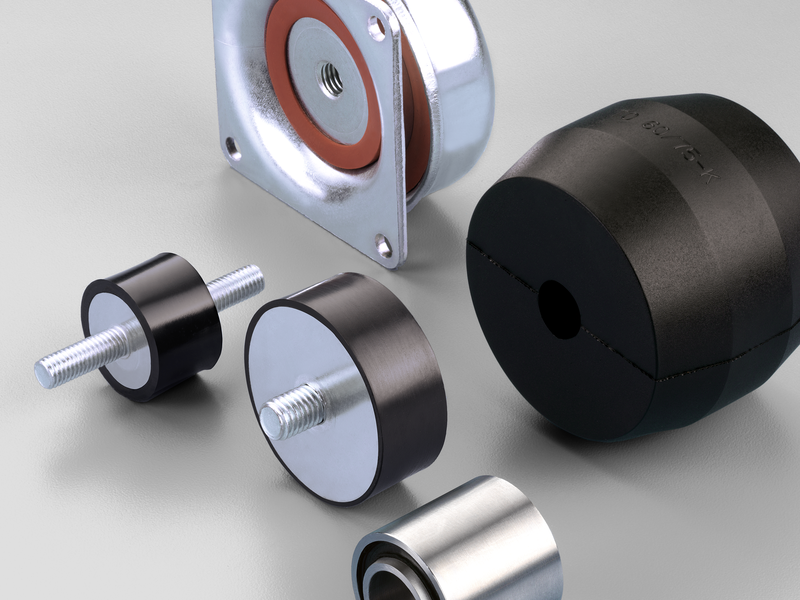

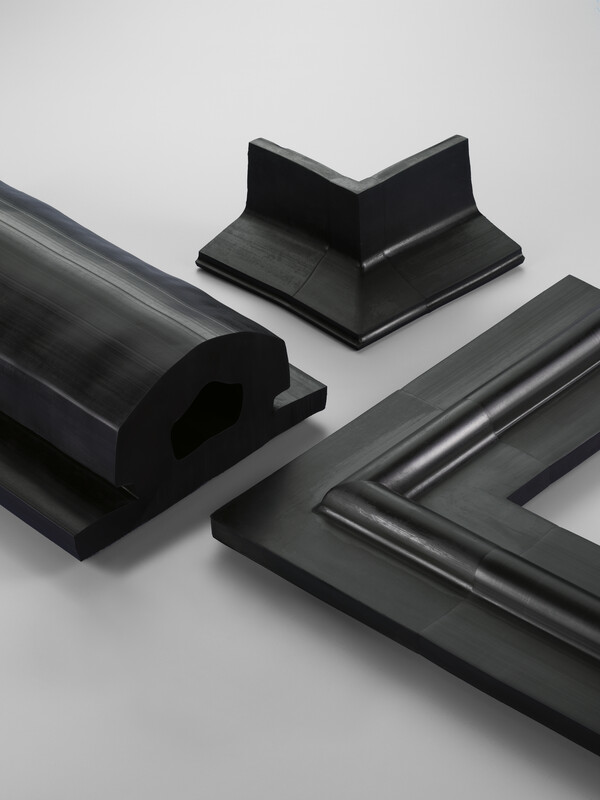

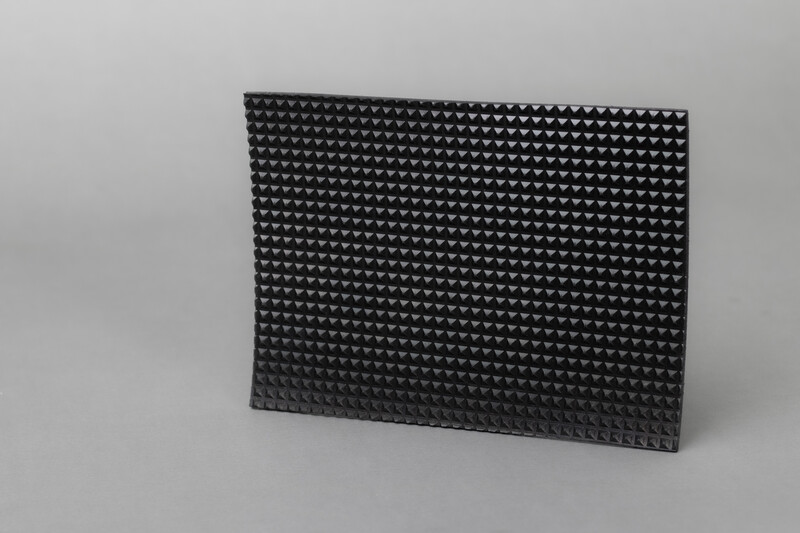

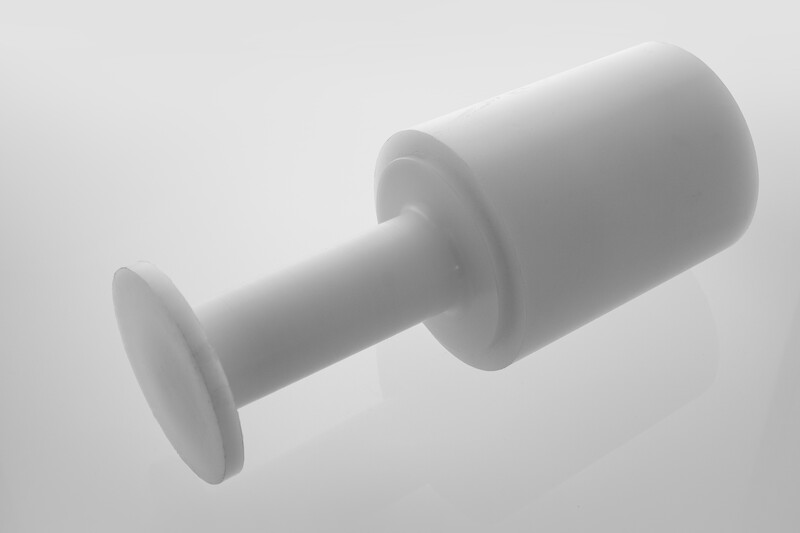

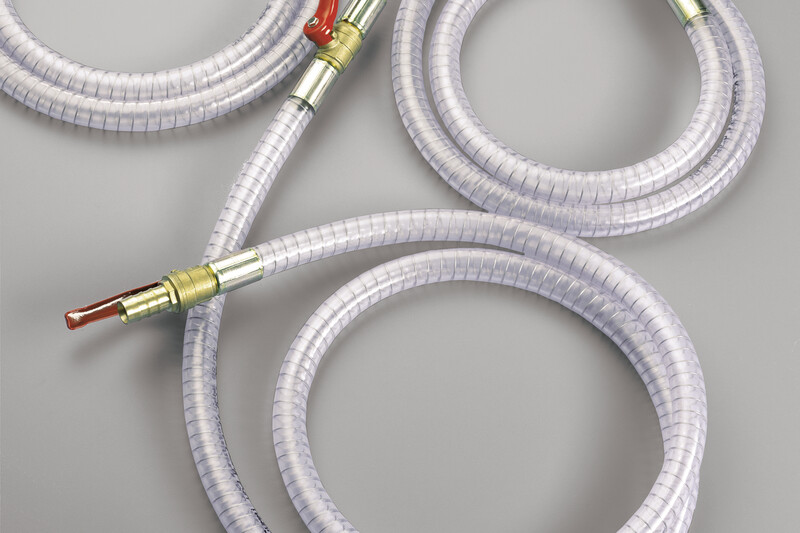

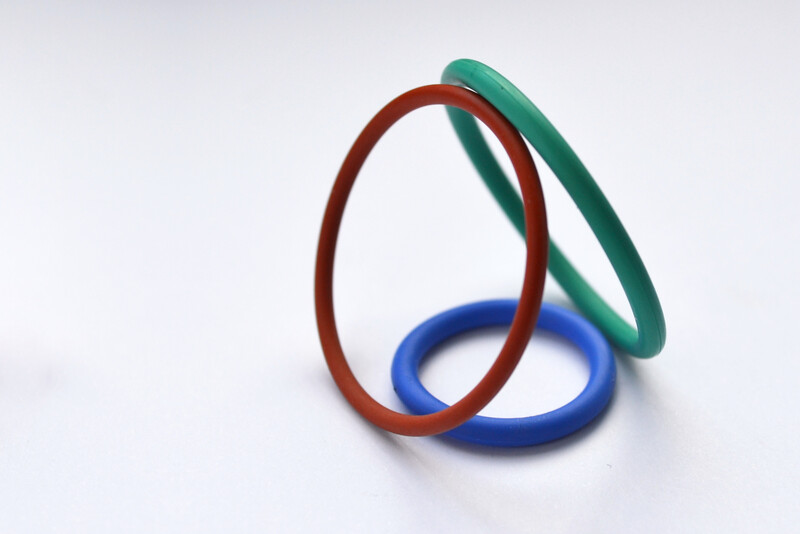

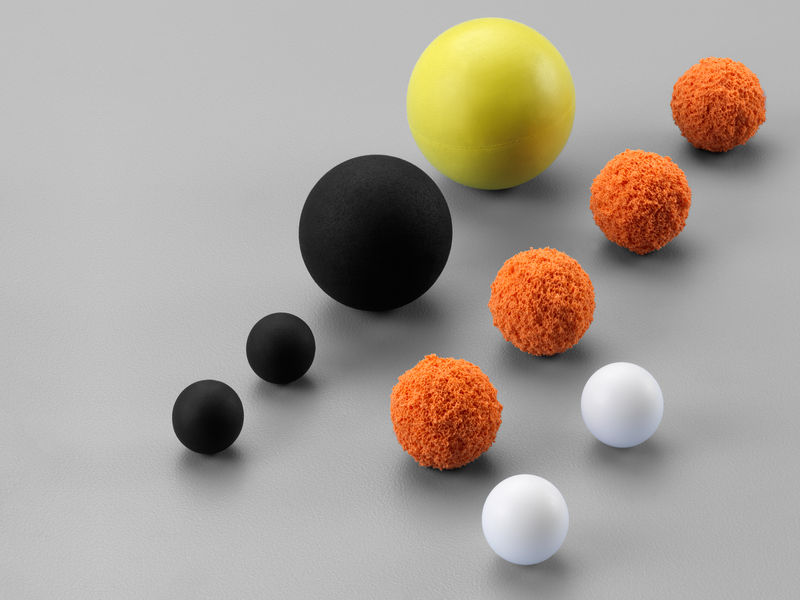

Our wide range of rubber and plastic products reflects our more than 80 years of experience in sealing, insulating, damping and conveying.

We have developed customized solutions for many standard applications in mechanical engineering and combined them into a stock range.

Cost-effective thanks to large quantities, available at short notice thanks to extensive stockholding and a wide range of materials without tool costs.

If test results confirm basic suitability, but potential for improvement can still be identified, our development engineers will make suggestions.

Receive your preferred product sample free of charge by filling out our request form. Our team will be happy to assist you!

Product portfolio

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161

Sie haben noch Fragen oder benötigen weitere Informationen?

Kein Problem!

Füllen Sie einfach unser Kontaktformular aus. Unser Team wird sich umgehend mit Ihnen in Verbindung setzen, um alle Ihre Anliegen zu klären.