THE ORIGINAL FULL PACKAGE SLIDE-OUT SEALING SYSTEM

Modern recreational vehicles now boast an array of features and conveniences, catering to outdoor enthusiasts who crave both adventure and the comforts of home. For those looking to maximize interior space, the ‘slide-out system’ is a game-changer. At Jaeger-UniTek Sealing Solutions, we’ve engineered the comprehensive Flip ‘N Seal Slide-Out Sealing System to elevate your RV experience. This all-inclusive sealing solution comprises the renowned Flip ‘N Seal, AquaDiverter, StyleCap, FlushFloor Reinforcer, and Hidewire Technology to prevent water intrusion and protect your RV.

The Original Flip 'N Seal®

While the “Slide-Out System” delivers an outstanding solution to maximize interior RV space, protecting the interior space from the outside elements creates a significant design engineering challenge. The sealing system plays a significant role in creating a watertight interior, minimizing temperature intrusions while delivering durability under dynamic and static loading conditions over a wide range of temperatures.

By working closely with RV manufacturers in rapidly expanding the use of Jaeger Unitek Sealing Solutions Patented Flip ‘N Seal Slide-Out Sealing System®, together, we have met the complex application demands with Slide-Out sealing requirements. The results are a watertight seal, a one-part sealing solution vs. a two-piece design, lower installation costs during seal preparation and installation, and the elimination of warranty claims. For consumers, this translates into the growing use of RV slide-outs to create more interior space, protection from the outdoor elements, satisfaction and enjoyment in the great outdoors.

Quick Facts

- Proven automotive polymer sealing technology

- Full ultraviolet (UV) exposure validation to automotive weather-ability standards

- Meets demanding abrasion resistance and thermal aging requirements to deliver long-term performance

- Laboratory tested for exposure to automotive fluids, acids and corrosive materials for optimized performance

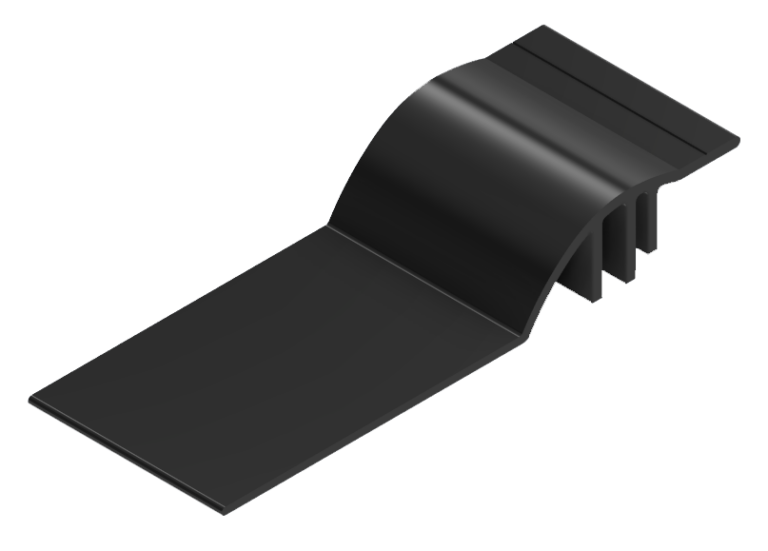

The AquaDiverter®

Introducing the AquaDiverter – another innovation from Jaeger-UniTek Sealing Solutions. Designed to complement our revolutionary Flip ‘N Seal sealing system for RV slideout rooms, the AquaDiverter was designed to manage water intrusion on both gear and cable driven slide-out mechanisms.

Quick Facts

- High impact, durable, engineered polymers to withstand the “over-the-road” dynamic and static loading conditions during travel

- Precise geometry with angled lip to seamlessly mate with the Flip ‘N Seal® family of products

- Reinforced ribs provide structural support for the slide-out mechanism, sloped horizontal surface with recessed side “troughs” for water evacuation

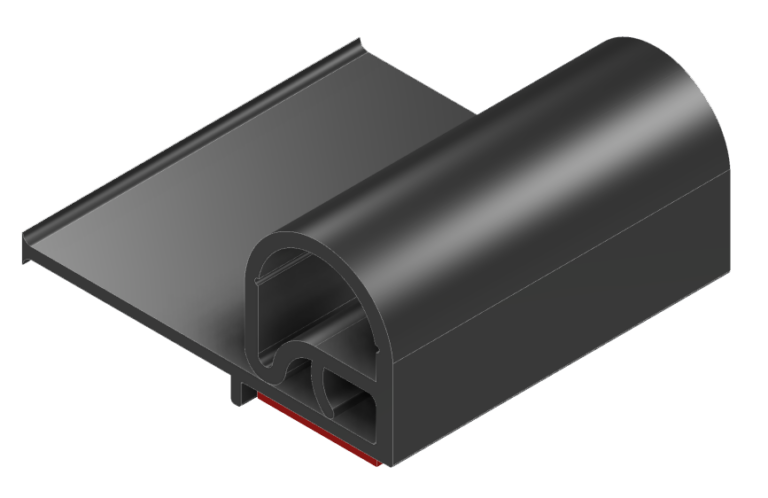

The StyleCap®

As the latest addition to the comprehensive Flip ‘N Seal slide-out system, the StyleCap is poised to set new standards in 2024 models. Developed as an addition to the Flip ‘N Seal system, the StyleCap seamlessly combines a polished finish with enhanced sealing at slide-out corners, satisfying the demand for elevated consumer styling and superior sealing performance.

Quick Facts

- Seamless fit with the proven Flip 'N Seal Slide-Out Sealing System

- Additional adhesive backed sealing protection

- Aesthetically pleasing design caps slide-out room corners

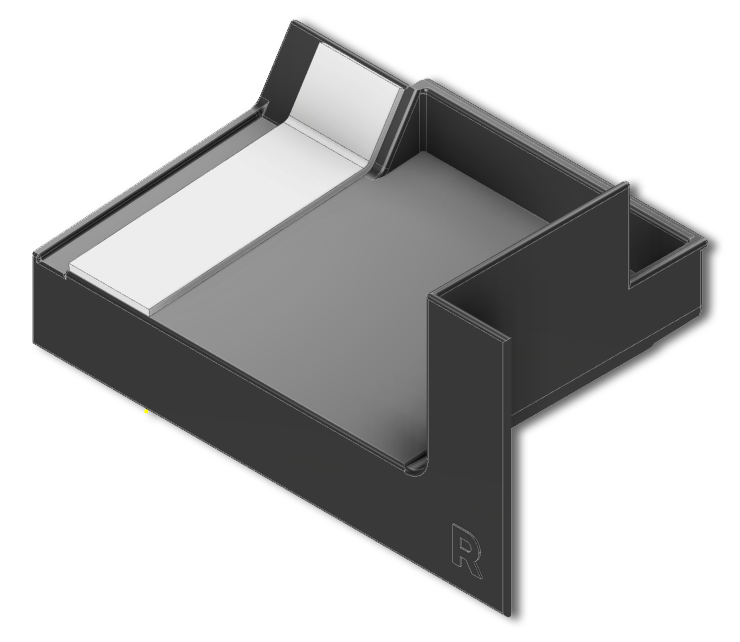

The FlushFloor Reinforcer®

The FlushFloor Reinforcer is your high-strength, all-in-one solution for structural reinforcement during flush floor slide-out room transitions.

Quick Facts

- High strength flush floor structural reinforcement designed to provide load carrying ability

- Consolidates multiple components into one integrated design for optimized mating with Jaeger’s patented bottom pans

- Innovative structural geometry with reinforcing ribs combined with a high modulus polymer for outstanding durability and impact strength

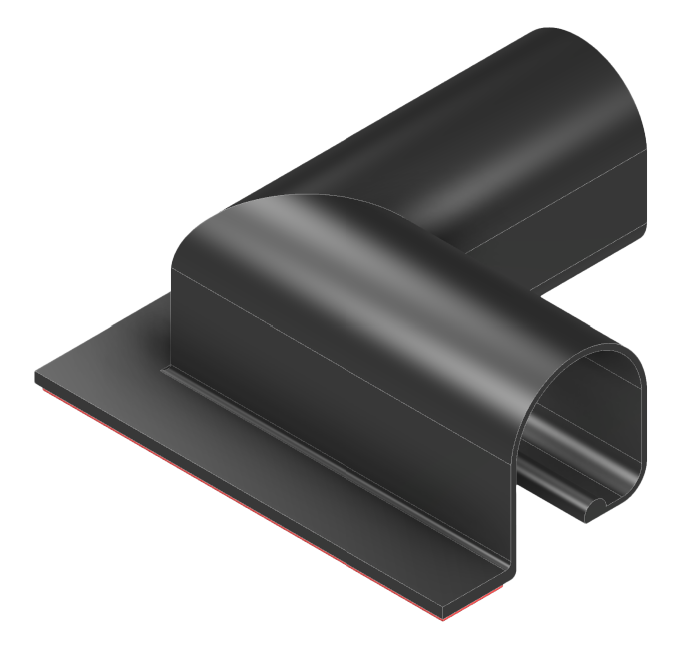

HideWire® Technology

Built upon the proven Flip ‘N Seal profile, the Flip ‘N Seal with HideWire Technology® goes a step further with the incorporation of a smart hook feature. Not only does it impeccably secure slide-out motor wire harnesses, but it also excels in concealing them, ensuring a sleek and tidy appearance. The HideWire Technology® takes installation processes to a new level, providing a seamless integration of form and function.

Quick Facts

- Designed for ease of assembly by RV OEM’s during slide-out mechanism installation

- Provides OEM’s with the ability to sole source their RV sealing package from slide-out mechanism producer to OEM

- Eliminates risks of an unrestrained wire during consumer use and slide-out cycling

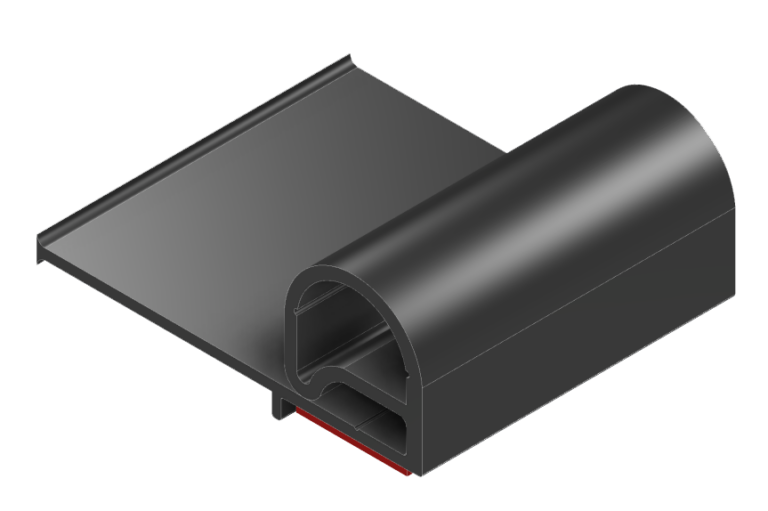

Design and Material Features

Being the most versatile seal available, the Flip ‘N Seal® Slide-Out System fulfills the most demanding requirements at the OEM, distributer and with end users. Using the highest performing automotive engineered grade polymers in the industry and manufactured in an automotive IATF Certified manufacturing facility, the Flip ‘N Seal® slide-out sealing system provides the complete package of sealing solutions in the recreational vehicle industry.

- Low compression set for effective and long-term sealing

- Patented one-component, integrated wipe and bulb for easy installation

- Proven automotive grade materials

- Exceptional UV weather-ability, combined with high performance heat aged temperature cycling

- Anti-friction coating for easy installation on line

- Reduced scrap & SKU consolidation by combining two components into one design

Quick Installation Guide

- 1. Clean and prepare the substrate surface with alcohol wipes for effective adhesion

- 2. Cut the top and side seals to desired lengths

- 3. Remove adhesive tape line from the back of the Flip 'N Seal®

- 4. Apply the side seals leaving the bulb flush with the top of the slide-out opening; trim to length at the bottom

- 5. Apply top seal across the header

- 6. Trim one end of each wipe and locator leg to 1/4-1/2 inch

- 7. Using staples or screws, mechanically fasten top and side seals behind the bulb

- Check out the full installation video!