Standardized or customized - solutions according to your wishes

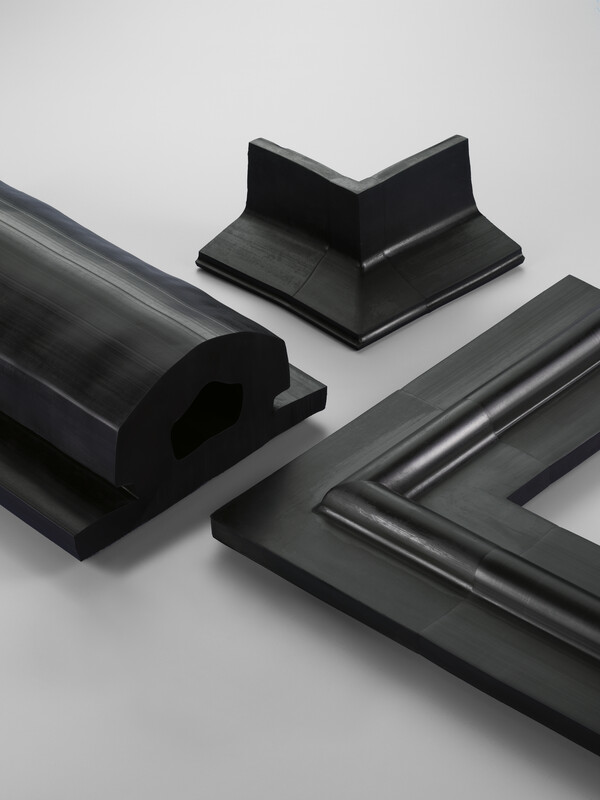

Whatever profiles you need, we will manufacture them especially for you. Tailor-made, designed to meet your specific requirements and guaranteed to produce the best results. Rubber and elastomer profiles produced in a continuous extrusion process are used as sealing or protective elements. The elastic material creates a sealing function by compressing the material or with the help of sealing lips. Depending on the area of application and requirements (environmental influences, temperatures, necessary restoring forces), we recommend the right elastomer, use our standard profiles available from stock or develop the right sealing solution for you.

On the other hand, plastic profiles are essential components in many industrial and commercial applications, which can be found in window frames, vehicles or in the home, for example. The plastic profiles are extremely versatile in terms of shape, color and cross-section size. They are also particularly resistant to environmental influences and remarkably durable. They are cost-efficient, low-maintenance and offer excellent insulating properties, making plastic profiles the first choice for sustainable construction and design projects. In addition, they are generally largely recyclable, which benefits the consumption of natural resources.

Quickfacts Profiles

Application

Sealing, protecting, covering, insulating, etc.

Materials

Cross section

Finish

Roll, reel, stretched lying, customized, cut to length (fixed length), with and without metal insert, with additives (e.g. flocking)

Manufacture

Extrusion process

Color

Plastic: can be colored as desired, rubber: on request

| Application | Sealing, protecting, covering, insulating, etc. |

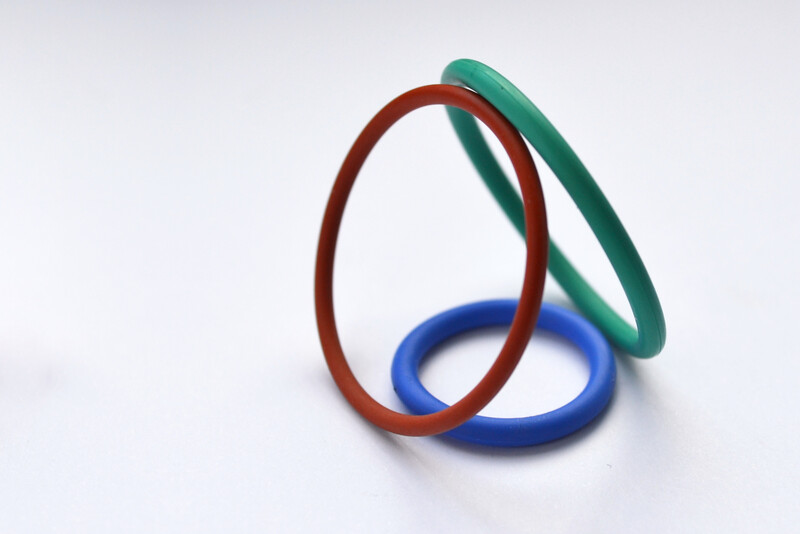

| Materials | Rubber: as solid material (EPDM, NR, SBR, NBR, CR, silicone, FKM) or foamed material (sponge rubber, cellular rubber) Plastic: PVC, PP, PE, TPE, PA, other materials possible |

| Cross section | on request (standard or according to customer-specific drawing) |

| Finish | Roll, reel, stretched lying, customized, cut to length (fixed length), with and without metal insert, with additives (e.g. flocking) |

| Manufacture | Extrusion process |

| Color | Plastic: can be colored as desired, rubber: on request |

Request a free sample now

Weitere Details im Katalog

Entdecken Sie weitere Informationen in unserem umfangreichen Produktkatalog.

Jetzt kostenloses Muster anfragen

Kurzer Erklärungstext zum verfahren oder ähnliches

Case Study

Blog

Blog

Blog

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161