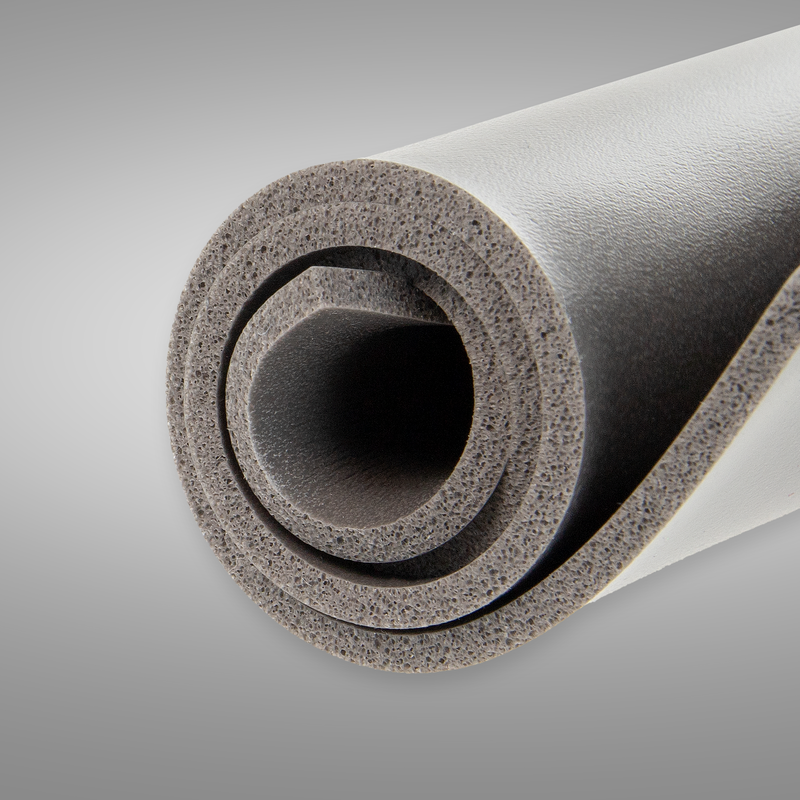

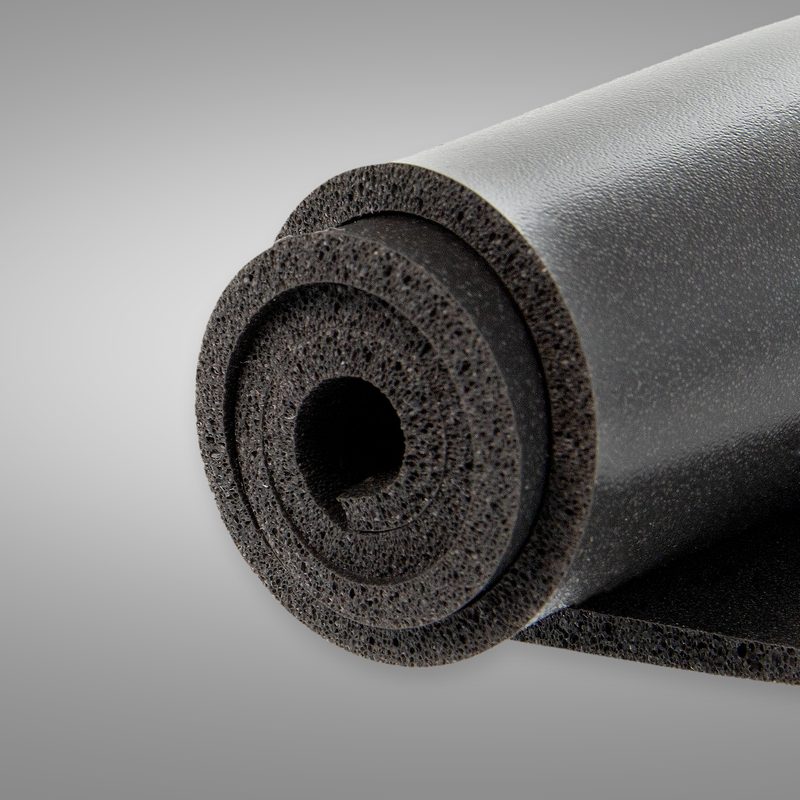

High-performance silicone foams

Futureway® is the leading manufacturer of silicone foams in China and Jäger Gummi und Kunstoff is the exclusive partner for the import and distribution of the SRL foam series to our customers and market participants.

Futureway was founded in 2010 by a group of ambitious and tech-savvy Fortune 500 entrepreneurs. With a focus on specialty silicone materials for the automotive (e-mobility), aerospace, transportation, semiconductor and big data industries, Futureway has quickly developed products of the highest quality.

The typical advantages of silicone, such as resistance to ozone and UV light, a wide range of chemicals and high temperatures, are just one argument in Futureway’s favor. The SRL series is also characterized by excellent compression values and certified fire and flame resistance. Made for applications that have to meet the highest standards.

Quickfacts High-performance silicone foams

Application

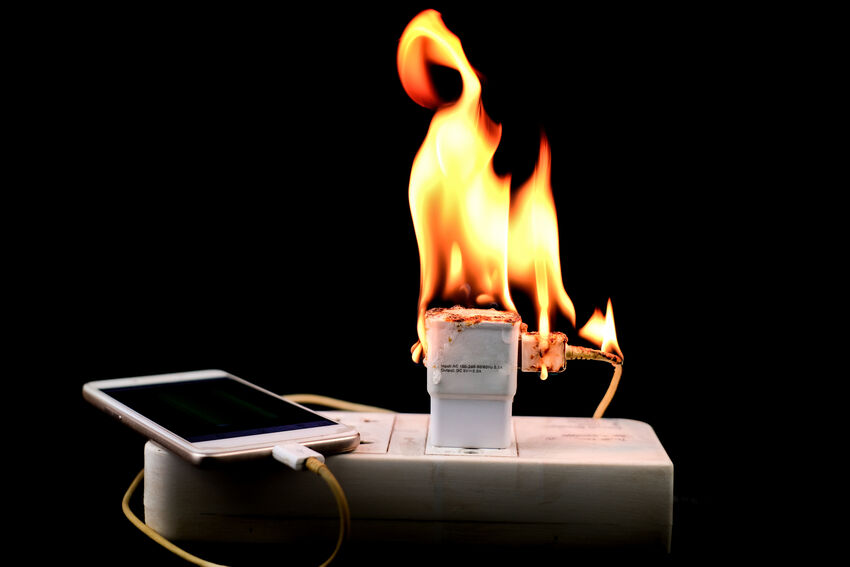

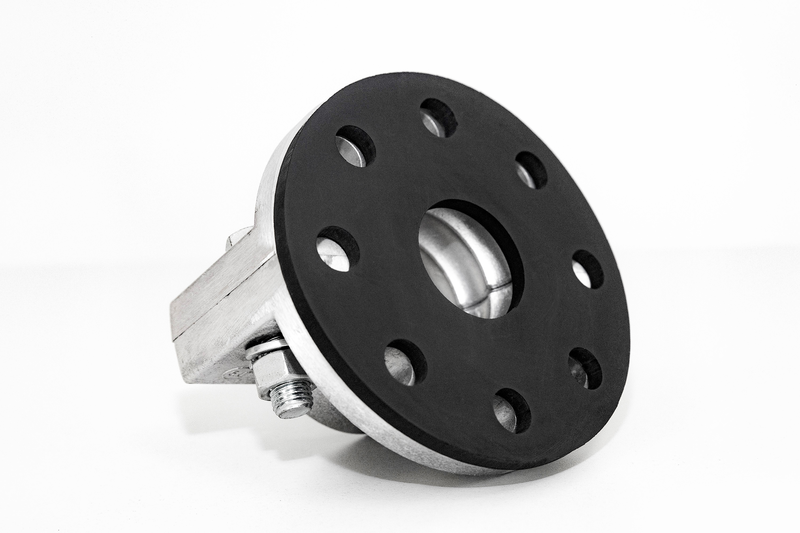

Sealing, insulating, damping (e.g. battery technology)

Variations

Foam sheets and roll goods with UL94V0 certification

Materials

MVQ, VMQ

Density

from 160g/cm3 – 600g/cm³ depending on type

Manufacture

Calendered LSR silicones in rolls, on request also as finished stamped parts (according to drawing), strips or PADs

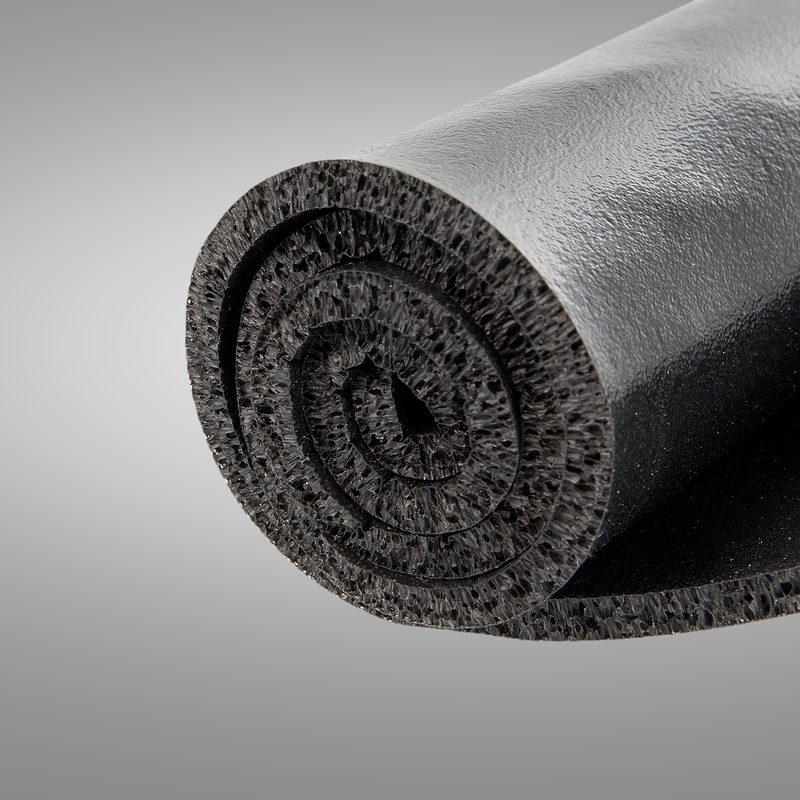

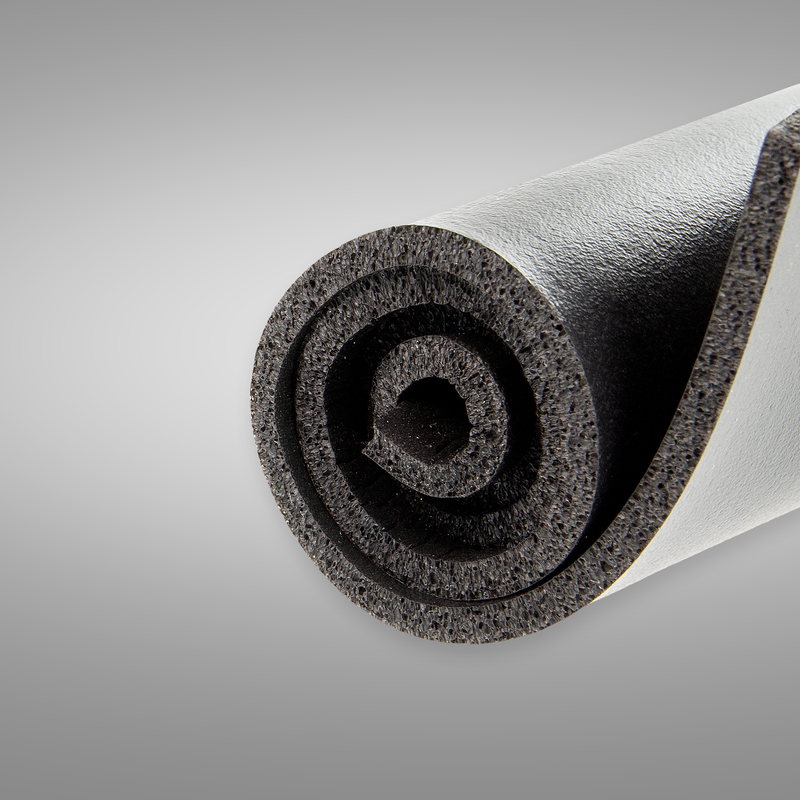

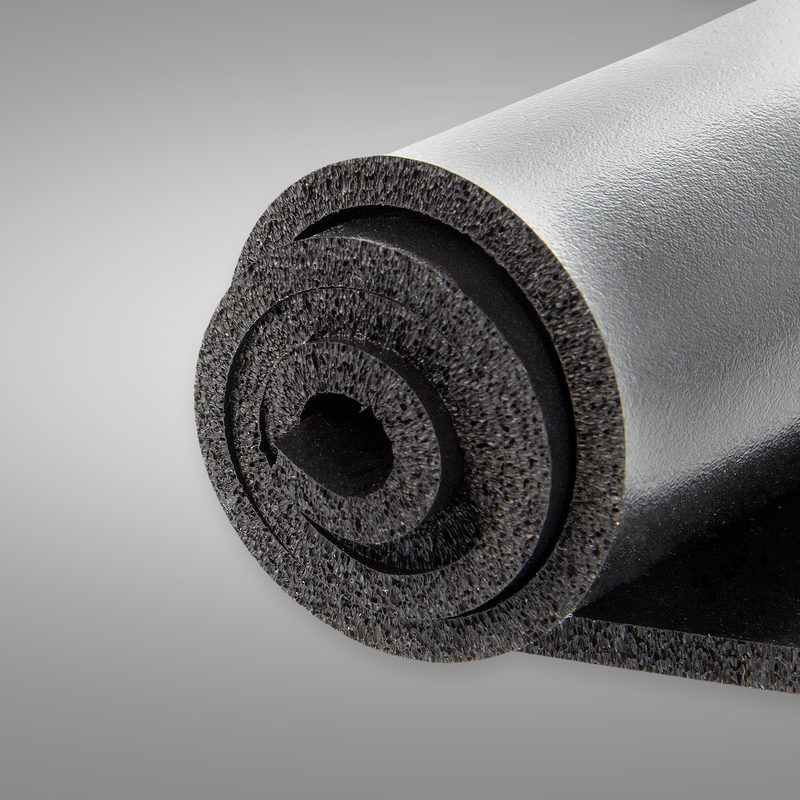

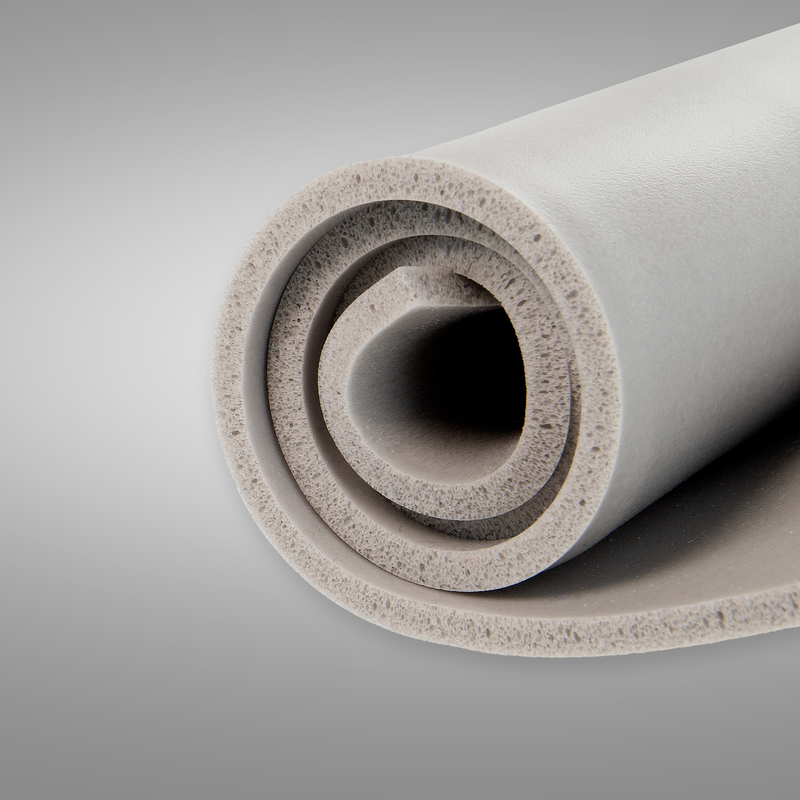

Colors

light gray, dark gray and black

| Application | Sealing, insulating, damping (e.g. battery technology) |

| Variations | Foam sheets and roll goods with UL94V0 certification |

| Materials | MVQ, VMQ |

| Density | from 160g/cm3 - 600g/cm³ depending on type |

| Manufacture | Calendered LSR silicones in rolls, on request also as finished stamped parts (according to drawing), strips or PADs |

| Colors | light gray, dark gray and black |

Request a free sample now

Further details in the catalog

Request a free sample now

SRL1130S

SRL1130F

SRL1140S

SRL1140F

SRL1150S

SRL1150F

Futureway offers non-alkaluminized foams made of LSR (liquid silicone). These are most comparable to the foams in the Rogers Bisco® range.

Due to the currently still tight supply chains and long delivery times for competitor materials, we are pleased to be able to offer Futureway as an attractively priced, quickly available and high-quality alternative.

We would be happy to sample the relevant materials to convince our customers of the value of our products.

Case Study

Blog

Fire protection is an important topic in the plastics and rubber sector. In particular, companies should be familiar with the two standards UL94 and DIN EN45545.

Blog

Seals often cause delays and additional costs in the development of machines and devices. How can such problems be avoided?

Blog

In sealing technology, it is essential to know the practical framework conditions- from application temperature to legal requirements.

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161