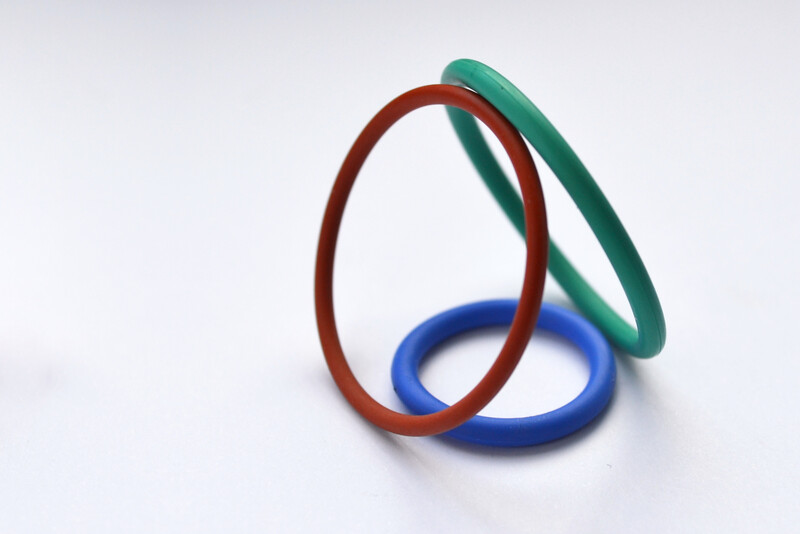

Reliable elements of sealing technology

Quickfacts O-rings

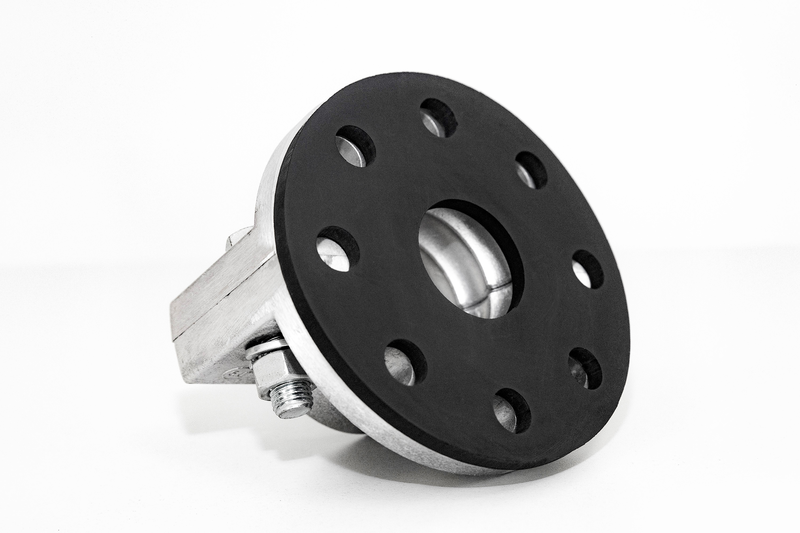

Application

Materials

Inner diameter (d1)

Cord thickness (d2)

Variants

Quantity

Manufacture

CM, IM

Advantages

Color

| Application | Static sealing elements, retaining rings, rotary seals |

| Materials | NBR, FKM, HNBR, FFKM, EPDM, PTFE, CR, PU, silicone, AEM, ACM |

| Inner diameter (d1) | 0.74 to 1400 mm |

| Cord thickness (d2) | 0.6 to 30 mm |

| Variants | With or without coating (siliconized, PTFE coated) |

| Quantity | depending on order volume |

| Manufacture | CM, IM |

| Advantages | Simple installation, good service life with correct design |

| Color | Standard black or colored |

Request a free sample now

Further details in the catalog

Request a free sample now

O-rings made of EPDM and NBR

We supply O-rings in the following versions:

Blog

Blog

Blog

Blog

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161