Perfectly matched to the application

Quick facts molded rubber parts

Application

Damping, sealing, insulating, protecting, etc.

Materials

NR, SBR, IR, BR, NBR, EPDM, CR, ECO, ACM, Silicone

Hardness

20 ± 5 Shore A to 90 ± 5 Shore A

Manufacture

CM, TM, IM

Quantity

Dimensions

Colors

Standard black or customized

| Application | Damping, sealing, insulating, protecting, etc. |

| Materials | NR, SBR, IR, BR, NBR, EPDM, CR, ECO, ACM, Silicone |

| Hardness | 20 ± 5 Shore A to 90 ± 5 Shore A |

| Manufacture | CM, TM, IM |

| Quantity | on request |

| Dimensions | on request |

| Colors | Standard black or customized |

Request a free sample now

Further details in the catalog

Request a free sample now

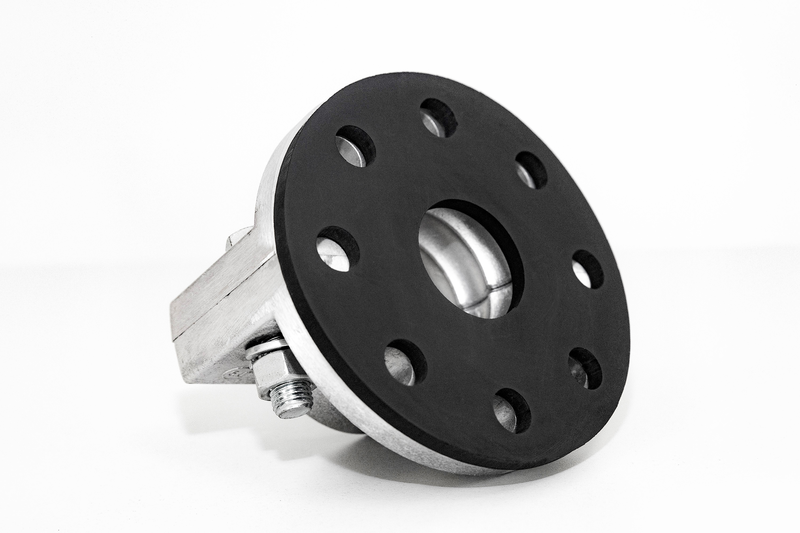

Molded rubber parts play a crucial role in a wide range of industries by performing essential functions such as damping, sealing, insulation and protection. Their flexibility and adaptability open up almost unlimited possibilities – from rubber buffers and seals to specialized applications in mechanical and plant engineering, the electrical and automotive industries, energy technology and agricultural and environmental technology.

By working closely with our customers, we do not develop standardized products, but individually adapted solutions that are designed to meet specific requirements. This collaborative approach to product development guarantees that each part is perfectly matched to its function and operating conditions.

Our moulded rubber parts are characterized by their elasticity, compressive strength, abrasion resistance and mechanical and chemical resilience. The choice of material and manufacturing process is carefully selected based on the specific application conditions and desired functions. With a wide range of manufacturing processes, we can react flexibly to the needs of our customers, regardless of whether it is individual production, series production or mass production. Thanks to our various possibilities within the JÄGER Group and our strategic partners, we are able to fulfill this variety of production requirements efficiently and precisely.

Each production process has specific characteristics and must therefore be precisely tailored to the order to be produced and the associated purchase quantities. We are able to handle both individual and series production as well as mass production within the JÄGER Group or via our strategic partners.

Blog

Rubber production is an energy-intensive process. Therefore, you should already proceed intelligently and methodically with the material selection.

Blog

Whether metal or plastic – particularly strict requirements apply to materials in the food sector. Find out more on the Jäger blog!

Blog

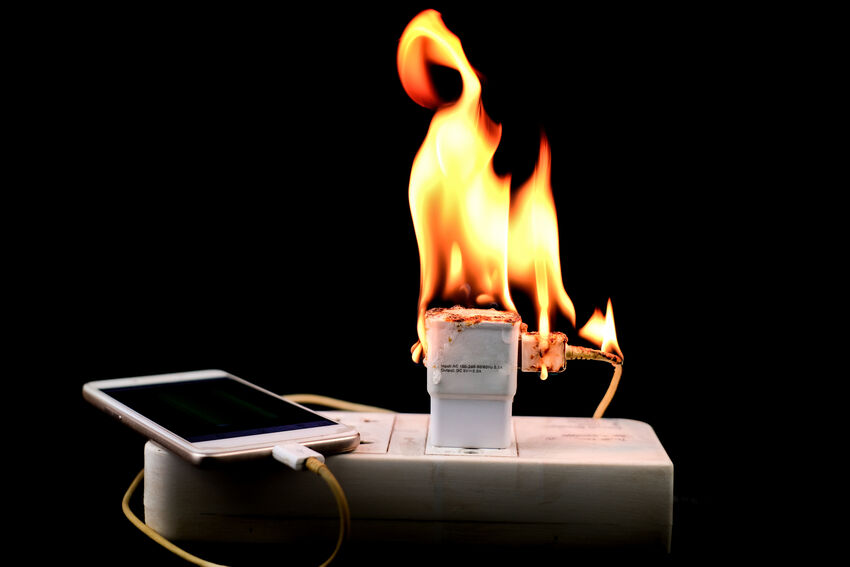

Fire protection is an important topic in the plastics and rubber sector. In particular, companies should be familiar with the two standards UL94 and DIN EN45545.

Blog

In sealing technology, it is essential to know the practical framework conditions- from application temperature to legal requirements.

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161