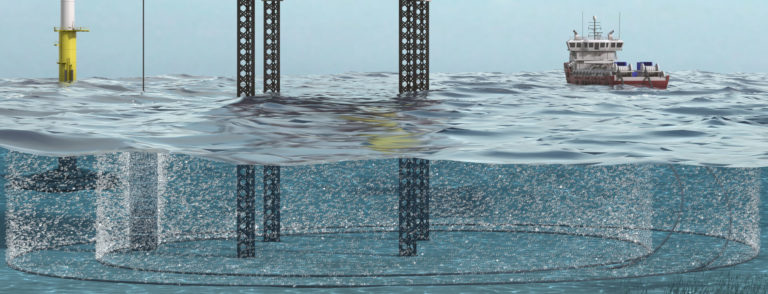

You will receive a noise mitigation system from Jaeger Maritime Solutions GmbH which is customised to your requirements. Beside the tried and tested conventional Big Bubble Curtain (BBC), we provide two new systems for reduction of naval sonars.

Underwater jobs such as laying foundations or detonations of munition can cause substantial sound emissions. Particularly the construction of offshore wind turbines causes noise which can adversely affect sea dwellers. With its Big Bubble Curtain, Jaeger Maritime Solutions GmbH contributes to the protection of marine animals during rammings of the heavy offshore foundations. For the benefit of the kind-protected porpoises, differently defined noise level limit values must be adhered to. The goal of Jaeger Maritime Solutions is not merely the adherence to these values but a general minimisation of sound emissions.

On the lookout for a durable and ecologically harmless corrosion protection? We provide more than that!

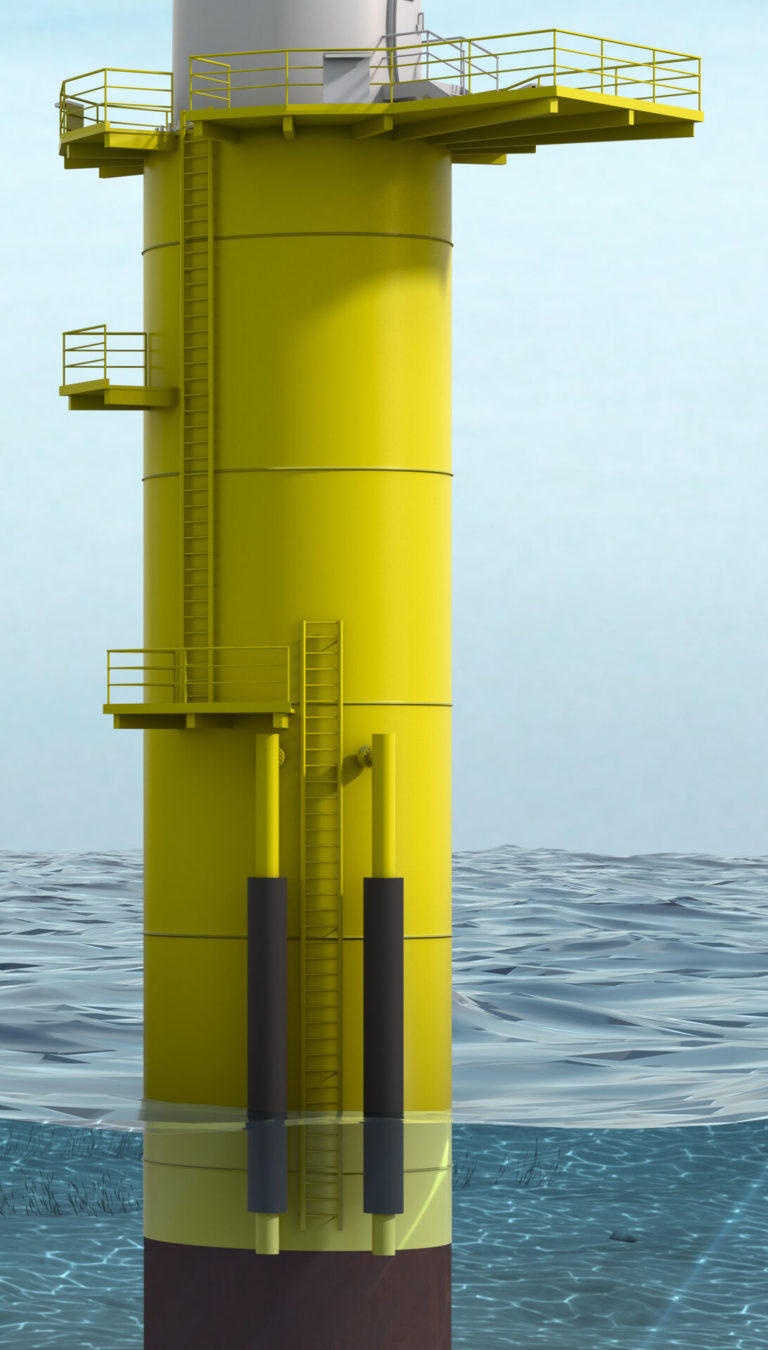

Jaeger Maritime Solutions GmbH produces protectors made from a composition of basalt fibers which protect steel constructions in the offshore domain both from corrosion and mechanical loads. Simultaneously, the increased friction between the steel construction and the rubber fender facilitates safer climbing for technicians. Thanks to the long service life of our protectors you also decrease your maintenance costs many times over.

The boat landings of wind turbines are exposed to particularly high stresses – maintenance boats damage the surface coating of the boat landing when docking due to the up and down movement of the waves.

The Jaeger Maritime Solutions GmbH protectors provide relief: the hard shells made of basalt fiber and vinyl ester resin which are attached to the fender pipes using an adhesive specially designed for this domain of application – similar to a shin guard. This may occur both onshore and offshore.

As basalt is a natural product it is also non-poisonous and thus absolutely future-proof. And this is what Jaeger protectors must be, because, even in cold and salty seawater and high UV exposure, our protectors exhibit a very long service life thanks to the basalt fabric.

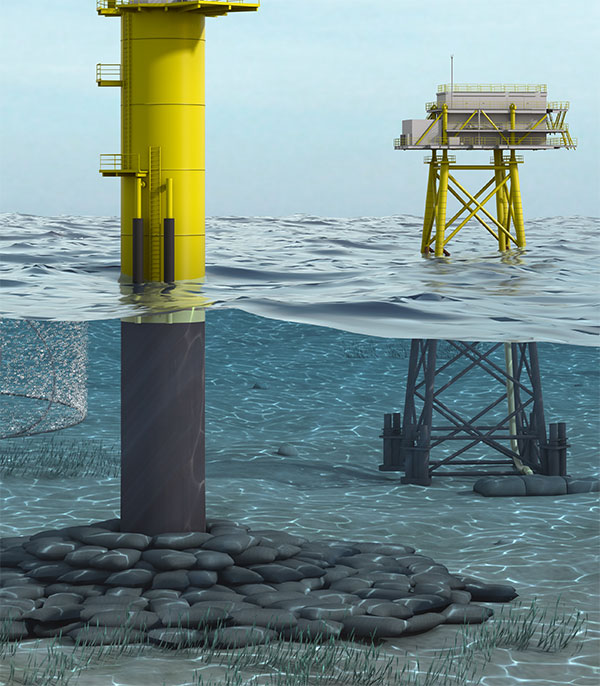

We provide an individual protection from flushing out and undercutting at sea and in inland waters – with our Jaeger Maritime Solutions GmbH basalt bags. The application possibilities of basalt bags are unlimited – let’s think outside the box together. Developed for offshore applications, the potential behind the idea is emerging stronger by the day.

Particularly the offshore wind turbines face the challenge of seabed layers around the foundation being carried off by the ocean currents. Usually, this process is counteracted by depositing stones. However, this does not always solve the challenge. Partially, the rock required for stopping the scouring process is not available in the region.

Jaeger Maritime Solutions GmbH basalt bags are a flexible and ecologically friendly solution. The sacks are made from a specially developed basalt fiber and are comfortably filled with round gravel or sand on site. Beside the application as scour protection, our Jaeger basalt bags can also be used for ballasting submarine cables or pipelines and as attachment in dyke construction and coastal engineering.

The porpoise is classified as a strictly protected species according to the German Nature Conservation Act because it considered endangered and its population is regressing.

Porpoises communicate with clicking sounds and orient themselves under water using sound. Hearing is therefore essential for the survival of the porpoise and is damaged from approximately 164 decibels. The impulsive noise as created by ramming can temporarily or permanently damage the hearing of mammals.

At Jaeger Maritime Solutions GmbH we are therefore always occupied with the improvement of our sound insulation system. Since the end of 2013, the German sound insulation concept for the construction of offshore wind parks has entered force at the German North Sea. The application of bubble curtain is recommended as a noise reduction measure.

Join us in positively contributing to a better environment.

Jaeger Maritime Solutions GmbH

Lohweg 1, 30559 Hanover (Germany)

Tel. +49 511 – 5358 0

Fax +49 511 – 5533 94

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH