BestBelt Feed Belts — Editing Options

|

|

Width (in mm) max

|

Length (mm) from

|

Length (mm) to

|

|---|---|---|---|

|

Dimensions

|

1380

|

2000

|

15500

|

|

Dimensions

|

1600

|

2750

|

15500

|

|

Dimensions

|

2800

|

4100

|

on request

|

|

Sanding

|

2.450

|

2.300

|

16.000

|

|

Drilling

|

2.400

|

2.300

|

16.000

|

|

Drilling

|

Ø 2.0 — 9.5 mm

|

||

|

Connection

|

Finger-Connection, V‑Connection, Straight-Connection

|

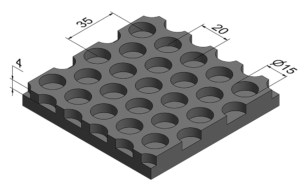

Circular hole

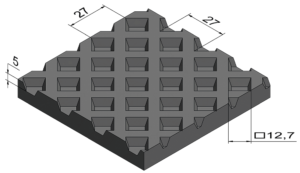

1/2 ” Diamond

1″ Diamond

Smooth

1 Tension ply + 1 Sliding ply

2 Tension ply + 1 Sliding ply

3 Tension ply + 1 Sliding ply

Our feed belts consist of four elements: the cover plate with different profile variants, the tension member, the intermediate rubber and the sliding layer.

We offer our cover plates with different surface structures — they are specially adapted to the material and the type of processing you are doing. Our highly abrasion-resistant sliding layers for wet and dry grinding as well as low-stretch tension member fabrics combined with intermediate rubbers are characterized by consistent product quality. Innovative joining techniques also provide maximum durability.

Cover plate

The rubber of the cover plate is a composition of various base polymers NR/NBR/SBR/EPDM. The predominant part consists of natural rubber (NR). The temperature endurance load should ideally be between ‑15°C to +60°C. The structure of the cover plate is adapted to your process task — you choose between circular hole, diamond or smooth side.

The static friction of the cover plate is approx. 0.95μ when delivered with fresh grinding.

Intermediate rubber

The intermediate rubber is made of natural rubber, thus it offers high flexibility and good functionality.

Fabric

The tension member fabric is a synthetic fabric developed for straight running, made of polyester (running direction) and polyamide (transverse to the running direction). In the running direction it is tensioned up to max. 1% related to the open length of the belt. The endless splice has a maximum breaking strength of approx. 60% of the base belt.

Sliding ply

The sliding ply made of polyester is characterized by material-protecting sliding properties, high abrasion resistance and good stretch properties; it is also insensitive to moisture.

ARTEMIS Kautschuk- und

Kunststoff-Technik GmbH

Tel. +49 511 — 959280

info@artemis-kautschuk.de

www.artemis-kautschuk.de

ARTEMIS Kautschuk- und Kunststoff-Technik GmbH

Rothwiese 4, 30559 Hannover (Germany)

Tel. +49 511 - 95928 0

Fax +49 511 - 95928 55

info@artemis-kautschuk.de

Arnold Jäger Holding GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH