REACHING THE NEXT LEVEL!

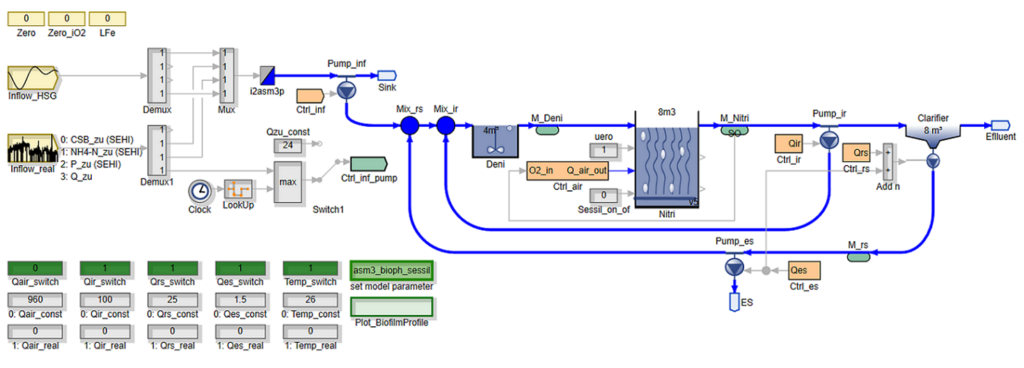

In close cooperation with you, we prepare a free comparison of different aeration systems with regard to their economic efficiency, based on the cost comparison calculation guidelines of LAWA (German Federal/State Working Group on Water)

Jäger Umwelt-Technik GmbH

Lohweg 1

30559 Hannover (Germany)

Tel. +49 511 – 64644 0

Fax +49 511 – 64644 499

info@jaeger-envirotech.com

www.jaeger-envirotech.com

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH