QUIET MOWING?

QUITE SIMPLE!

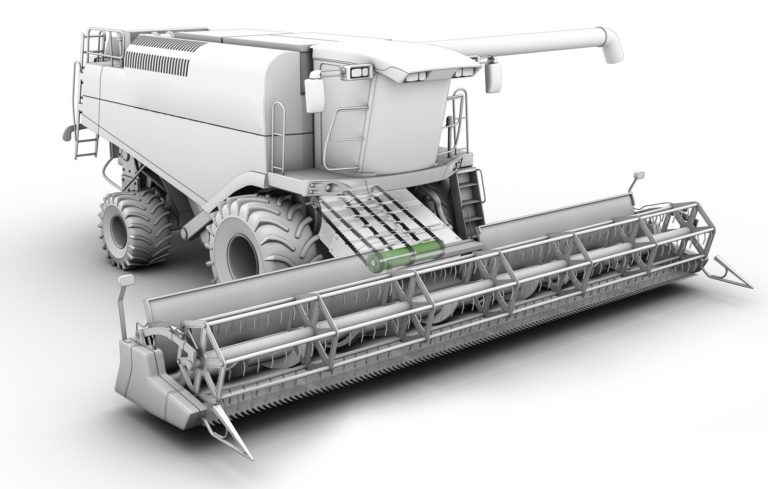

“Silentium Drive”, the innovative conveying system for combine harvesters with rubber-fabric traction belting with parabolic cams abolishes one of the major noises in combine harvesters and reduces wear of the inflexible all steel chain and its drive components.

Thanks to the impressive novelty made by Jäger, the tremendous noise of cross bars hitting the box sheet metal construction, as usual in conventionally provided combine harvesters, can be diminished.

Contact our experts:

Sales

Please select a valid form

– Netherlands –

Please select a valid form

– USA –

Please select a valid form

Arnold Jäger Holding GmbH

Lohweg 1

30559 Hannover (Germany)

Tel. +49 511 – 53580

Fax +49 511 – 553394

Management board:

Dipl.-Kfm. Marius Jäger

Dipl.-Ing Sebastian Jäger

Registercourt Hannover HRB 59983

DE 813 341 233

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH