IDEAL FOR ABRASIVE

AND HIGHLY VISCOUS MEDIA

We manufacture single‑, double- and multi-start rotors for all pumping tasks – adapted to the respective media and requirements. Together with our customers we develop innovative rotor geometries with special heads and create calculations and designs based on the latest 3D software.

In addition to our standard sizes, we also produce larger components up to a length of 8 metres for you. For rotors, we offer extensive coating techniques such as hard chrome plating and carbide coatings (e.g. tungsten carbide, chrome carbide) in order to guarantee maximum service life and minimize wear even with the most difficult pumping media in ever new areas of application.

New developments for the conveying technology, the creation of prototypes as well as all processing steps of the later series production can be carried out completely independently of external suppliers in our own company. Thus we offer the greatest possible security, also for your innovations!

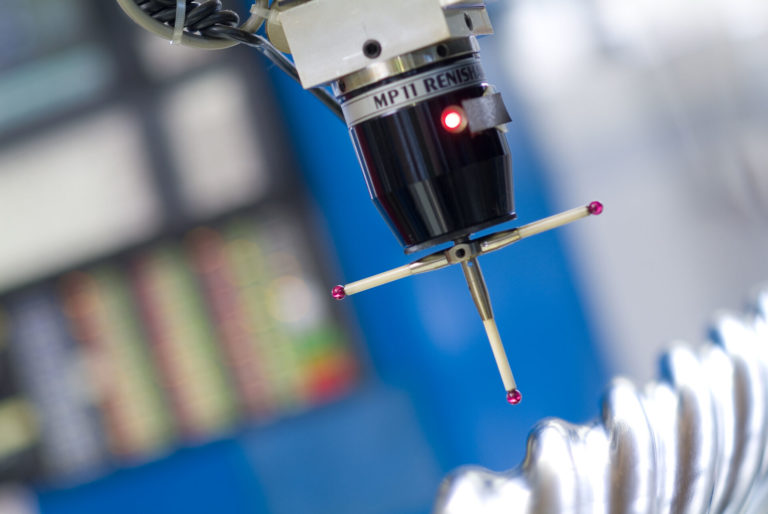

To ensure our high quality standards, we use the latest 3D coordinate measuring technology. Under the premise of precision at the highest level, the production facilities and machinery of the JÄGER Group are certified according to DIN EN ISO 9001:2000.

In our development and production processes, we pay attention to the perfect coordination of stator and rotor geometries to ensure optimum efficiency. We achieve this by using the latest 3D technology as well as simulations of the later operating behaviour of the rotor.

Contact our expert:

Sales Stators & Rotors

Please select a valid form

Arnold Jäger Holding GmbH

Lohweg 1

30559 Hannover (Germany)

Tel. +49 511 – 53580

Fax +49 511 – 553394

Management board:

Dipl.-Kfm. Marius Jäger

Dipl.-Ing Sebastian Jäger

Registercourt Hannover HRB 59983

DE 813 341 233

Arnold Jäger Holding GmbH

Artemis Kautschuk- und Kunststoff-Technik GmbH

Artemis PC Pump Systems Ltd.

Transportbandenfabriek EA Broekema B.V.

Broekema Beltway USA, Inc.

Jaeger Envirotech India Private Limited

Jäger Gummi und Kunststoff GmbH

Jaeger Maritime Solutions GmbH

Jaeger Polska Sp. z o.o.

Jaeger Rubber & Plastics (Shenzhen) Ltd.

Jäger Umwelt-Technik GmbH

Jaeger-Unitek Sealing Solutions, Inc.

Spira Systems, Ltd.

Windgassen GmbH